The machine adopts AC servo motor & driver to drive precision ball screw moving through decelerating system, adopts full digital controller as control system core controlling software & data processing by Windows system, makes wide range adjustment of testing speed to perform tensile, compression, bending, and flexural test for metal & non-metallic materials, the test process is stable & efficient with low noise. Thanks to the adopted international advanced control technology the test machine can achieve constant velocity deformation, displacement and test force controlling.

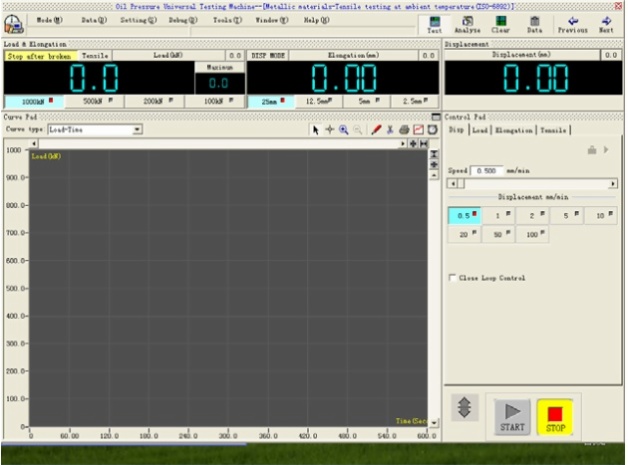

Parameters of test can be set through computer which automatically controls the test process, makes data acquisition, processing, analysis and display (the test data for metal materials includes: upper & lower yield points, tensile strength, fracture strength, elastic modulus, Elongation, δ0.2), etc., the test result is controlled precisely & accurately.

Equipped with dedicated software, according to national standards or user-provided standards, the machine can process test data, output or print required test curves or test reports, it is workable for user to select test curves of stress-strain, loading-time, loading-displacement, displacement-time or deformation-time to be displayed, enlarged, compared, and monitor the test process intelligently & conveniently.

The beam moving can be adjusted faster or slower when clamp on specimens, the switch can be operated easily.

The machine is with function of limit protection, overload or over current protection at any working position, reliable and safe.

With self-built test database, test data can be saved, queried and recalled at any time.

Benefit from highly automation of test process and installation of dozens of different fixtures, this machine can meet customer’s test requirements for various materials.

Standard:

ASTMA370,ASTME4,ASTME8,ASTME9,ISO6892,ISO7438,ISO7500-1,EN10002-4,

GB/T228-2002, etc.

Main Note for configure

- Motor: TECO from Taiwan ------if change to Panasonic brand need extra cost

- Load cell: made in China ------if change to Celtron brand need extra cost;

- Standard configure WITHOUT big deformation device and extensometer

- Standard Packing list

| Item | No. | Specification | Quantity | Remark |

| Main Product | 1 | Loading frame | 1PC | Total 1 Box |

| 2 | Computer for control | |||

| 3 | Printer | 1PC | ||

| Accessories | 1 | Clamps for Tensile | ||

| 2 | Clamps for Compression | |||

| Technical documents | 1 | Manual | 1PC | |

| 2 | Packing list | 1PC | ||

| 3 | Software Disk | 1PC | ||

| 4 | Certificate | 1PC |

Technical Specification:

| Max.loading capacity | 200KN / 300KN |

| Testing grade | class 1 |

| Loading measuring range | 0.4% -100% |

| Loading measuring accuracy | better than ± 1% |

| Displacement resolution | 0.01mm |

| Displacement measurement accuracy | ± 0.5% |

| Test speed range | 0.01-500mm / min |

| Vertical tensile space | 800mm (excluding fixture) |

| Vertical Compression space | 800mm?can be customized? |

| Compression plate diameter | 100mm?can be customized? |

| Test width | 400mm?can be customized? |

| Flat sample 0-26mm | |

| Fixture clamping | Round sample Φ9-32mm |

| (Wedge-shaped) | |

| Main unit size | Around 840 * 600 * 2200mm |

| Main unit weight | Around 1200Kg |

| Power supply | 220VAC 50HZ |