1. Single chip microcomputer control technique.LCD screen displays.English man-machine interaction interface.The heating power is continuously step-less adjustable.The rate of heating up is exact.Easy setting for parameters.

2. The LCD screen has prompting menu,prompting input operation interface.It shows the setted parameters,real-time temperatures and other test parameters.Press the “record”button when the flash point appears.The screen will show and reserve the flash point.

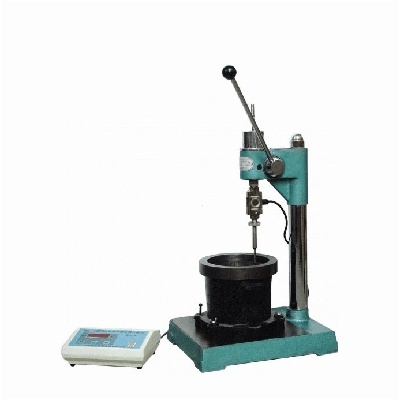

3. The structure is newly design and small.Stainless steel table-board looks clean and beautiful.It can be used as long as equipped with gas or other civilian fuels.It is easy to use and test results exact.

| Power supply | AC( 220±10% )V, 50Hz. |

| Heating device |

(1) The furnace is silicon carbide material. Power is 600W. (2) The heating power is adjustable from 0 W to 600W. |

| Heating rate |

Procedure A: (5?6)?/min, Procedure B:(1?1.6)?/min. Automatically controlled |

| Stirring device |

(1)Stirring motor: BYGH101 stepping motor (2) Driving mode: flexible shaft (3) Shaft size: 8mm×40mm

|

| Stirring rate | Procedure A: (90?120)RPM, Procedure B: (250±10)RPM |

| Igniting device |

(1) Igniting source: gas?or other civilian fuels?the same below? (2) Electric ignition. Gas flame diameter:3.2mm?4.8mm |

| Temperature testing probe | RTD, PT100 |

| Ambient temperature | ≤ 35? |

| Relative humidity | ≤ 85? |

| Maximum power consumption | 650W |