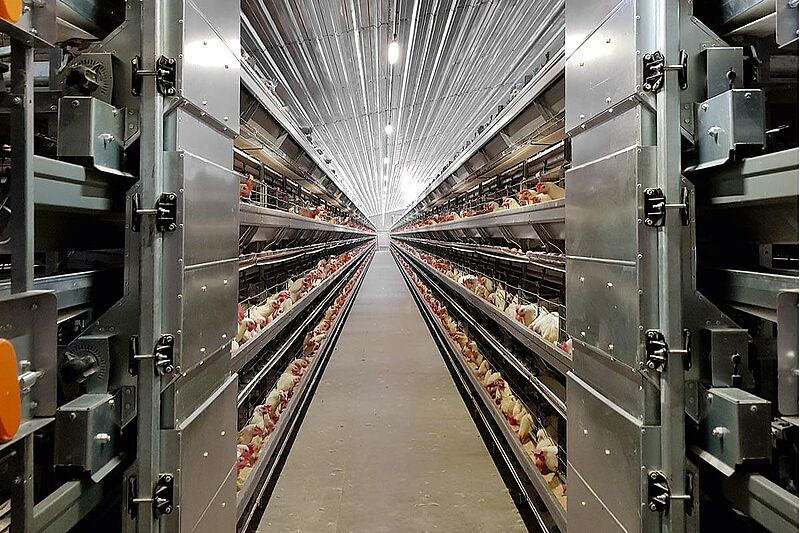

Flexible, efficient and gentle on the eggs

Egg collection systems play an important role in successful layer and breeder management, both with floor and cage production. This is mainly due to the following reasons:

- Reduced time and labour costs;

- Optimum egg quality, I.E. Cleaner eggs, few cracked eggs;

- Accurate count of the total number of eggs produced per tier, row or house.

Big dutchman egg collection systems meet even the highest requirements:

- Gentle transport of the eggs;

- High functional reliability;

- Easy handling.

St elevator

Ideal for short systems, reliable egg transport

The st (standard) elevator transfers eggs onto the elevator chain in a set pattern. This is to ensure that no eggs are transferred onto already occupied steps. If a barn houses birds of different age groups, st elevators can also be used to collect eggs per row or per flock. In order to match the conveying capacity and the laying performance, we recommend separately actuating egg belts and elevator chains.

With the st elevator, dosing wheels transport the eggs onto the elevator chain, from where they are moved downwards to the lower sliding grille. The chain turns here and then transports the eggs upwards to the desired height, where they are transferred onto the cross belt. The transfer can be carried out at any height; the standard height, however, is 2.10 m (q 210) to guarantee a clearance height of 1.95 m. If a manual collection table is installed, the transfer height lies at 80 cm (q 80).

Main advantages

- Large collection capacity of up to 16,500 eggs per hour and per elevator*;

- Easy access to all cage rows; the cross collection is not an obstruction;

- Less space required in the end set area;

- Suitable for all cage types.

* Depending on the system type, the egg belt width and the speed of the longitudinal belt