HTC – Hoek Triaxial Cell

EASY TO OPERATE

AVAILABLE IN SEVEN DIFFERENT DIAMETERS

HIGH PRESSURE CAPABILITY

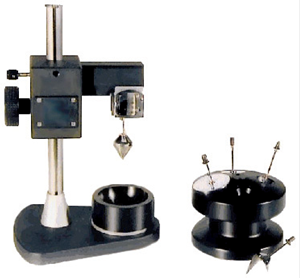

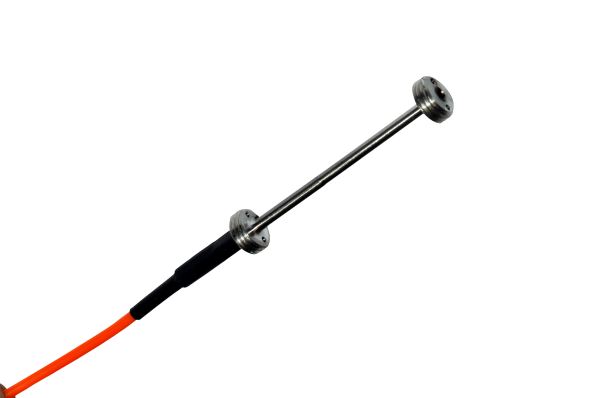

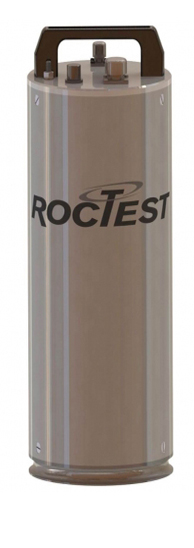

The Hoek Triaxial Cell is designed to determine the triaxial strength of diamond drill cores of rock or concrete.

HTC – Hoek Triaxial Cell

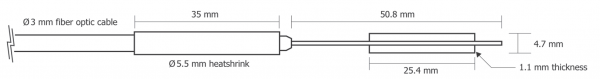

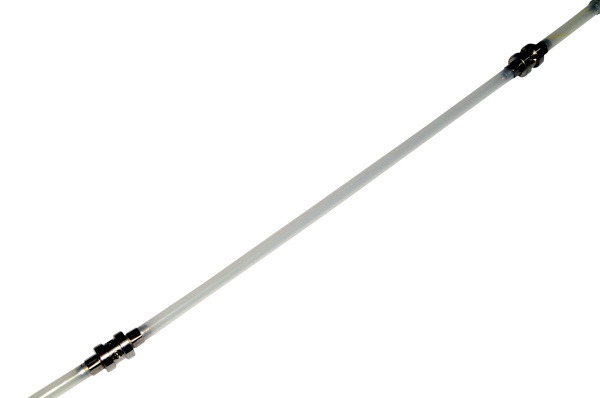

The HTC triaxial cell consists of a hollow steel cylinder with threaded removable ends. A urethane rubber sleeve incorporating U-shaped seals to form a pressurization chamber for the hydraulic fluid is mounted within the cell. Inside the cell is installed an inlet fitted with a 9.525 mm (3/8″) quick-connect and an outlet with a plug for the saturation of the pressurization chamber.

At each end of the cell is a spherical seat, which will apply an axial load to the flattened ends of the sample. This pair of seats is made of tool steel hardened and ground to ASTM (D2664) standard. The clearance gap between the seats and the removable ends of the cell is sufficient to allow the passage of strain gauge leads.

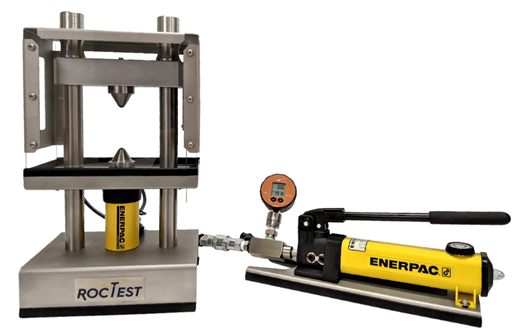

Test Procedure:

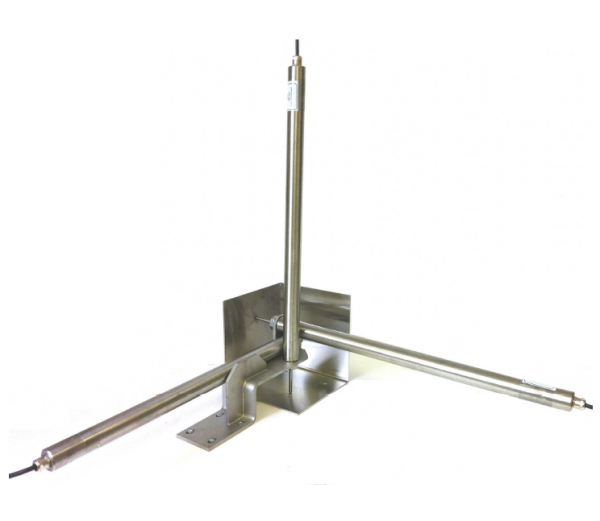

First, the ends of the rock specimen, with a minimum length to diameter ratio of 2, must be ground flat within a parallelism of 0.025 mm to 0.012 mm, depending on the diameter of the sample. After saturation of the pressurization chamber, the cylindrical rock sample is inserted into the chamber within the confining membrane. The two spherical seats are positioned so that the rock core lies centrally in the triaxial chamber.

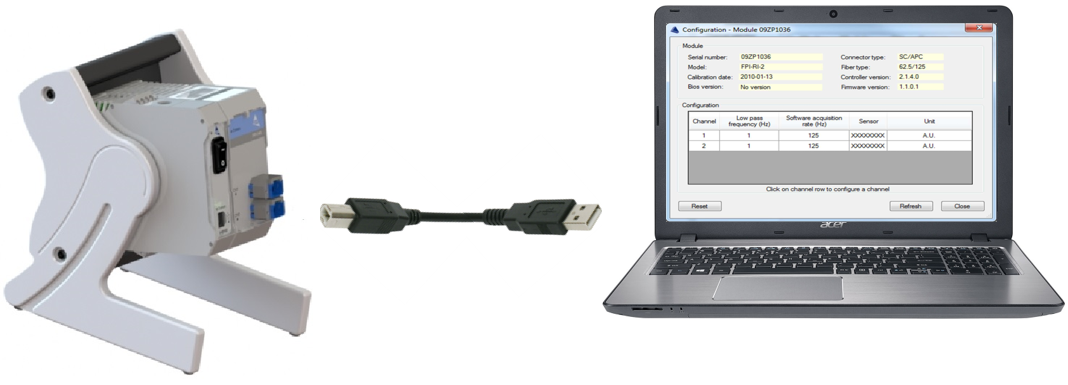

After applying a small confining pressure to hold the rock core in place, the cell with its spherical seats is placed in a loading frame and a small axial load is applied to hold the system firmly in place. To determine Poisson’s ratio, two orthogonal strain gauges are glued on the rock core. The strain gauges are read during the test with a Wheatstone bridge readout. The triaxial test may then be run after adjustment of the confining pressure to the required value.

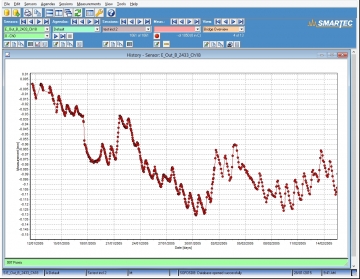

Test Results:

With the use of strain gauges, triaxial tests run on the same type of rocks at different confining pressures allow the determination of the failure envelope with the angle of friction and cohesion, the modulus of elasticity and Poisson’s ratio.

Specifications

| DESCRIPTION | SIZE1 | ||||

| AWG | BWG | NQ | NWG | HQ | |

| Triaxial cell complete with one quick connect and one plug | 1.185 in. (30.1 mm) | 1.655 in. (42.0 mm) | 1.875 in. (47.6 mm) | 2.155 in. (54.7 mm) | 2.500 in. (63.5 mm) |

| SPECIAL HOEK CELLS | |||||

|

144.7 mm (5.7 in.) diameter membrane |

|||||

|

152.4 mm (6.0 in.) diameter membrane |

|||||

| 1 Other sizes available upon request. | |||||

Ordering Info

Ordering information:

- Spherical seat platen

- Membrane (Not included)

- Set of two complete permeability end caps with distance block (for L/D = 1)

- Load spreader (set of 2)

- Flat platen

- Support collar

- Straight pore pressure platen

- Hydraulic pump 0–10 000 psi with pressure gauge 0–10 000 psi, hose and male quick connect to mate with cell

Optional accessories:

- Number of membranes (no membrane is included with an ordered cell)