DiTemp Self Heating Cable

DISRIBUTED FIBER OPTIC TEMPERATURE SENSOR WITH SELF-HEATING CAPABILITY FOR CIVIL, GEOTECHNICAL MONITORING AND LEAK DETECTION

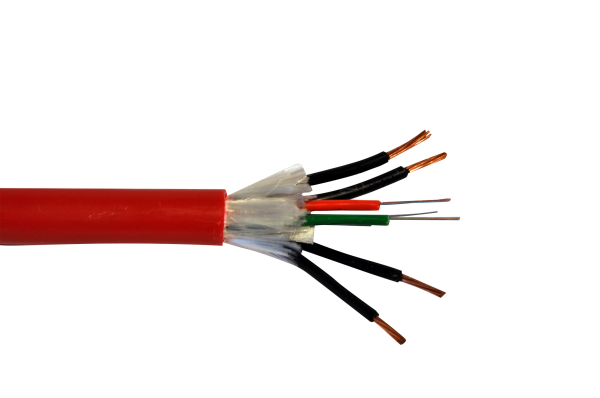

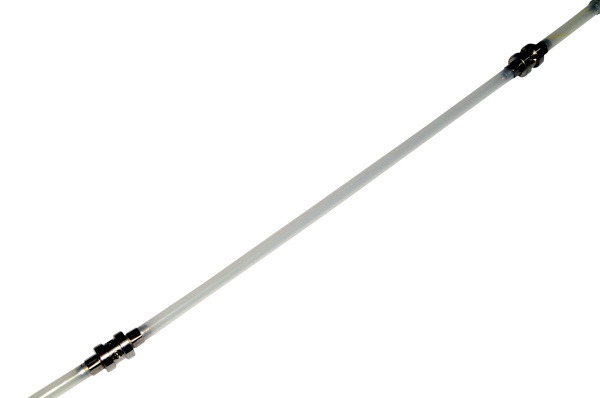

Reliable and versatile cable for easy installation.

Copper conductor for implementing heat-pulse method.

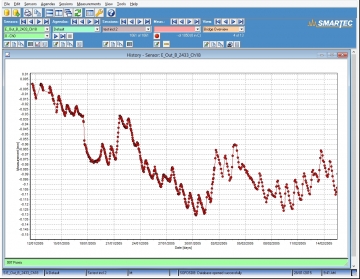

The Self Heating cable is a unique sensor for the evaluation of distributed temperature over distances up to 1 km.

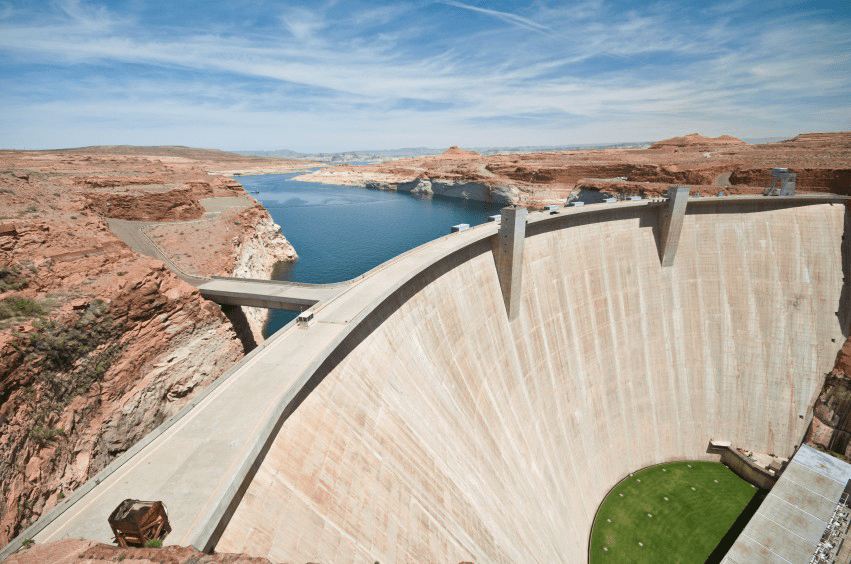

The Self Heating Cable is used in a range of hydro & geo-technical applications that require distributed temperature sensing, where the temperature contrast between the ground and the fluid to be monitored is not sufficient to provide a reliable detection. The Self Heating cable is particularly used in the seepage monitoring of dams, dikes, embankment and levees just to name a few.

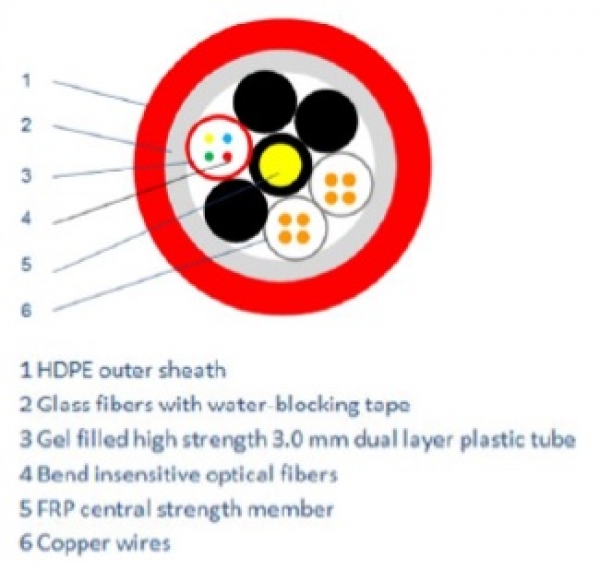

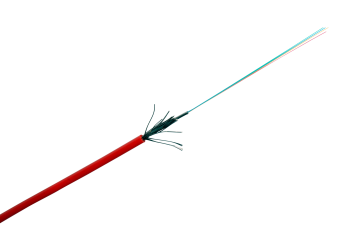

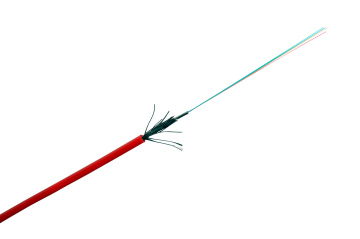

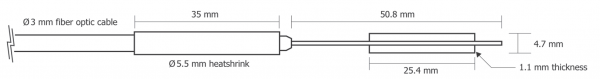

The Self Heating Cable is a small fiber optic cable, armored with stainless steel loose tube gel filled, stainless steel strength members and HDPE outer sheath. The central loose tube is hermetically sealed and contains 4 bend insensitive fibers with a dual layer acrylate coating for increased micro bending performance. The additional wiring, made of copper wires, permits to heat the cable thanks to the low resistivity.

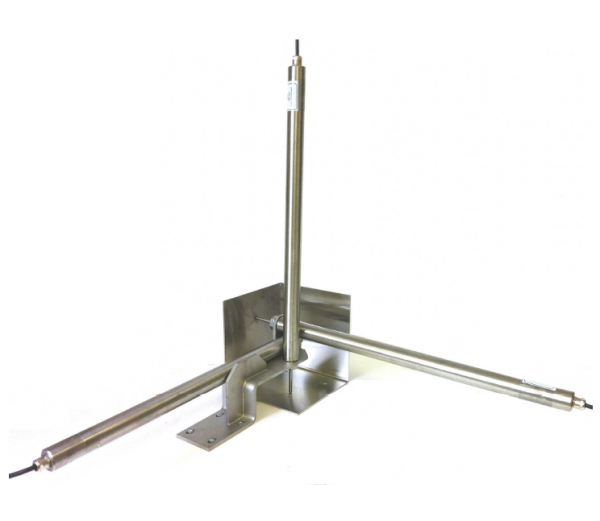

This sensor is particularly suitable for outdoors and harsh environment applications with different methodology of installation: direct burial in the ground or concrete.

Thanks to the special package design the Self Heating Cable offers high tensile strength, crush resistance, lateral water tightness, chemical and abrasion resistance and excellent rodent protection.

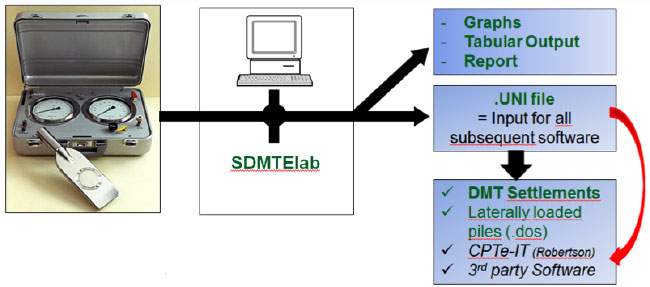

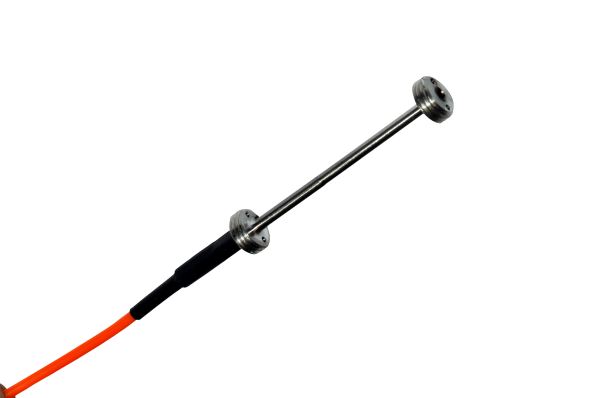

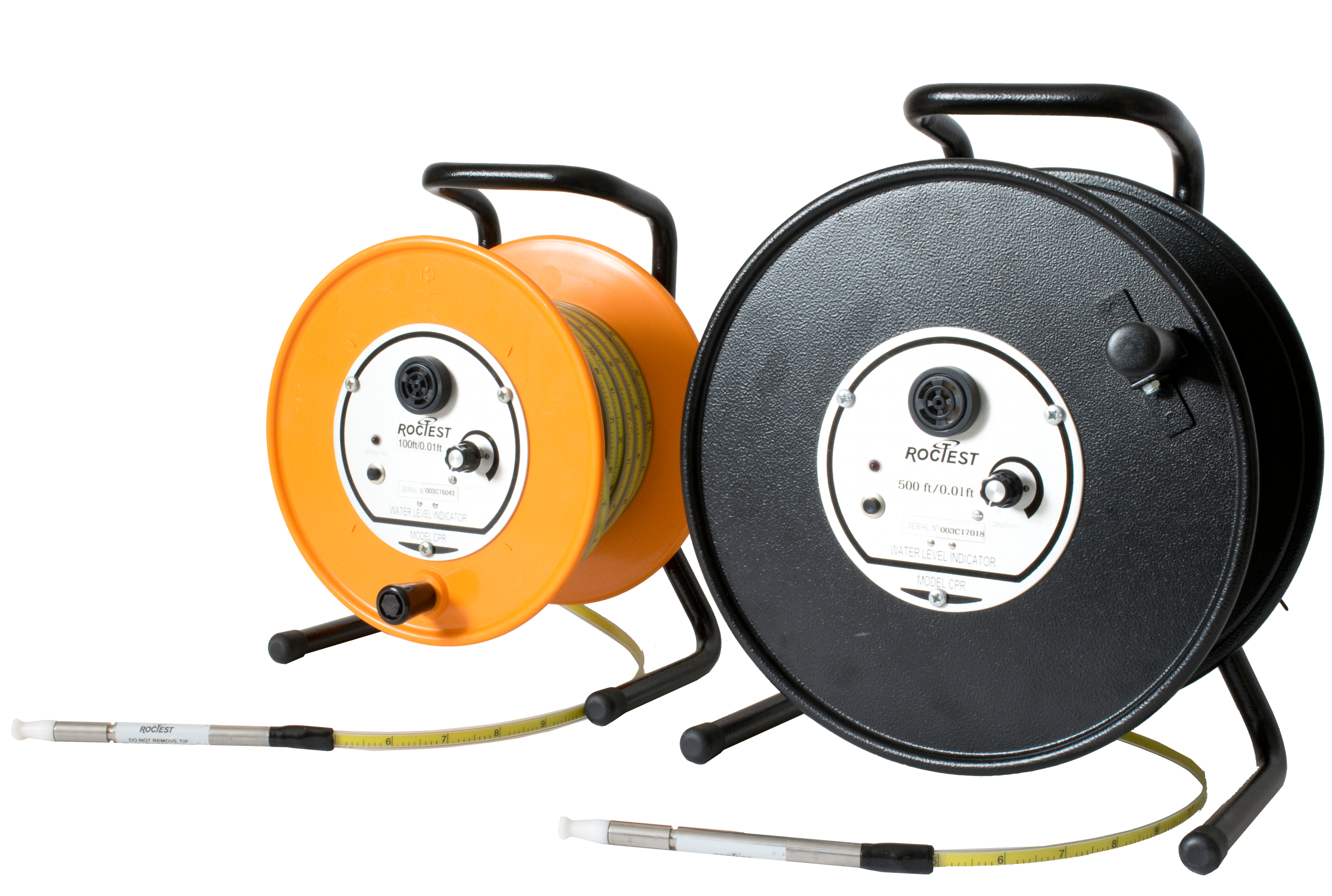

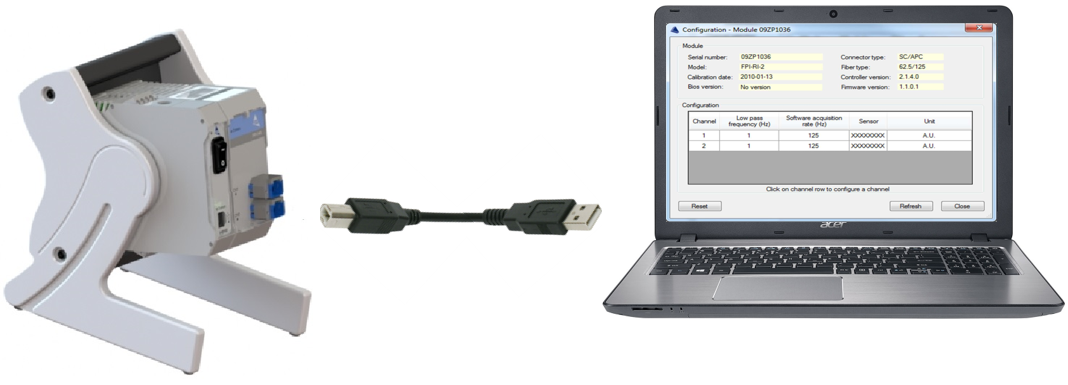

The Self Heating Cable is fully compatible with the DiTemp system and all its accessories.

Specifications

| Temperature range | |

| Operating temperature: | -40 °C to +70 °C |

| Storage temperature: | -40 °C to +70 °C |

| Installation temperature: | -10 °C to +50 °C |

| Technical Data | |

| Outer diameter: | 13.4 mm |

| Weight: | 150 kg/km |

| Max crush resistance: | 300 N/cm |

| Max tensile strength: | 6000 N (installation) |

| Max tensile strength: | 3500 N (operation) |

| Min bending radius: | 270 mm (with tensile) |

| Min bending radius: | 210 mm (without tensile) |

| Hydrostatic pressure: | 300 bar |

| Electrical technical data*: |

2x 4 Cu, 0.5 mm2 conductors (outer diameter 0.8 mm) Electrical resistance: 37 Ω / km, per conductor (* variants on request) |

| Fiber Types | |

| Fiber support: | 4 MMF 50 / 125 µm ITU-T G.651 compliant |

| Fiber attenuation (cabled @ 20 °C): |

≤ 3.0 dB @ 850 nm ≤ 1.0 dB @ 1300 nm |

| Number of fiber: | 4 |

Ordering Info

- Cable termination with optical and electrical connectors

- Heating module

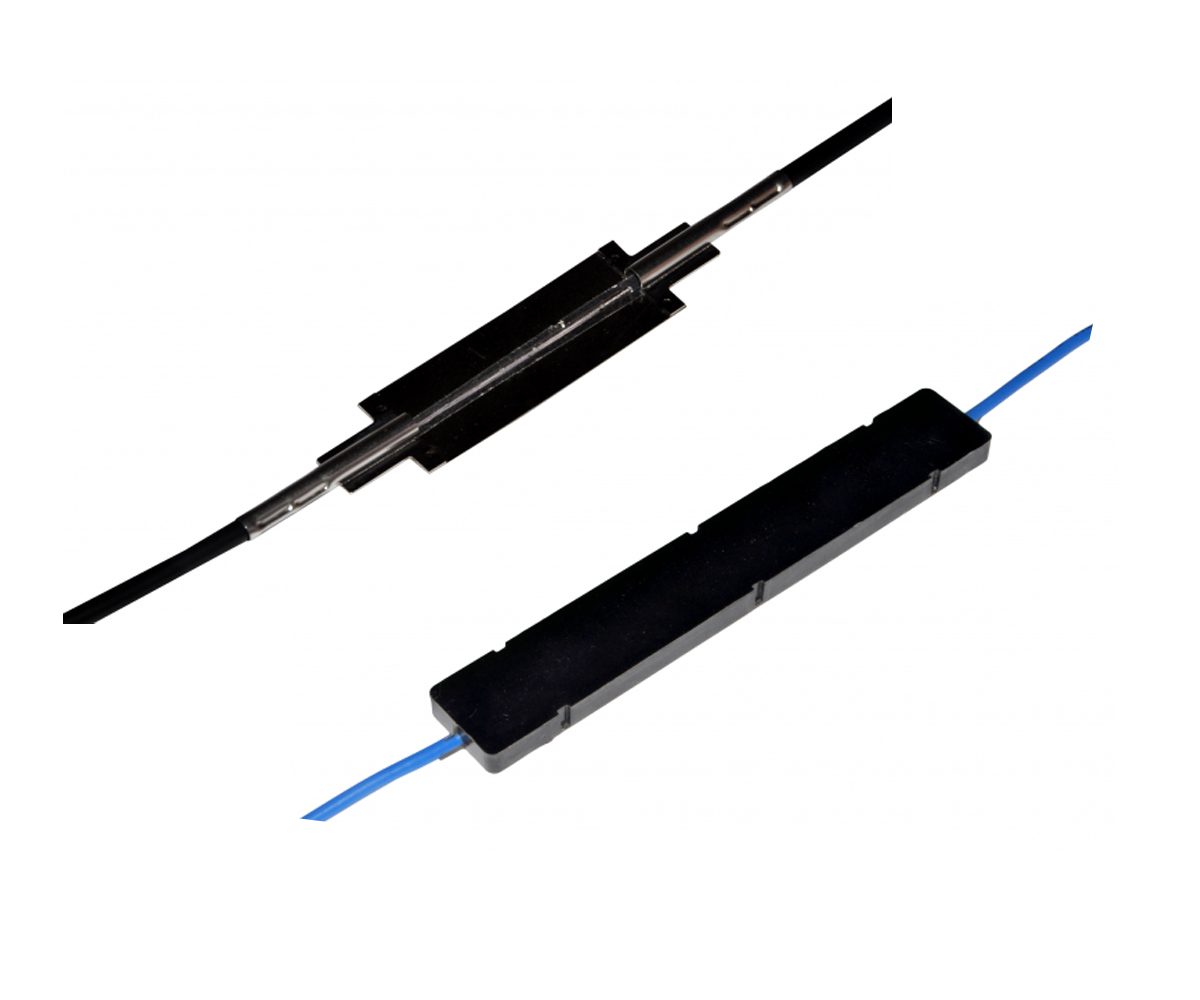

- Junction box

- Splice box