EM Series Embedded Vibrating Wire Strain Gauge

LONG-TERM RELIABILITY

HIGH RESOLUTION

3000 MICROSTRAIN RANGE

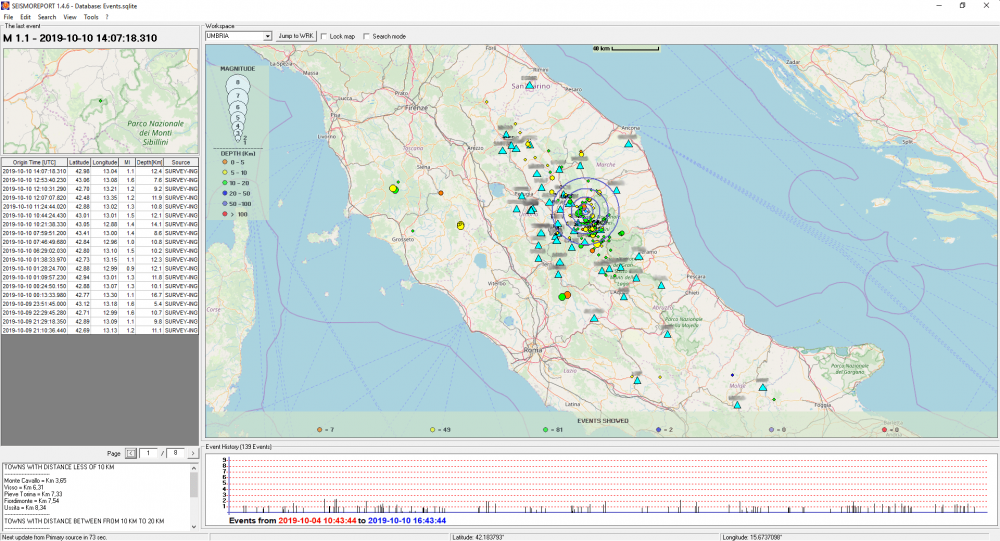

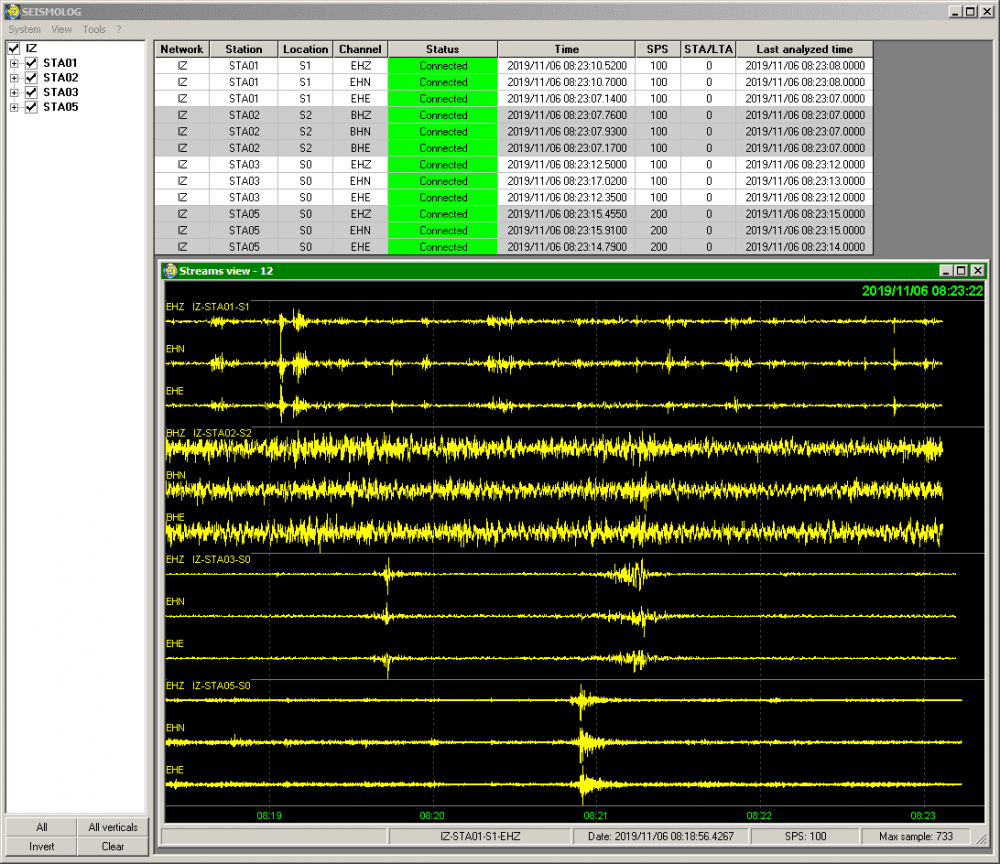

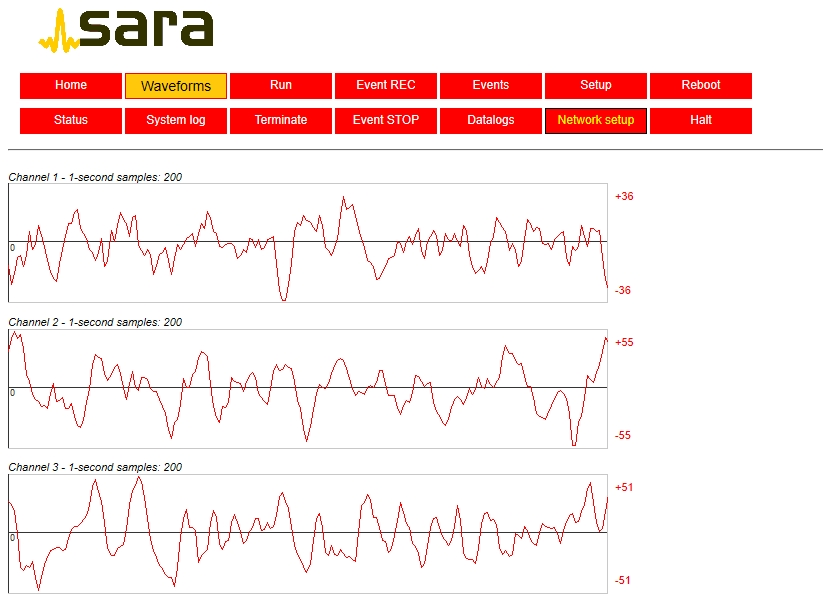

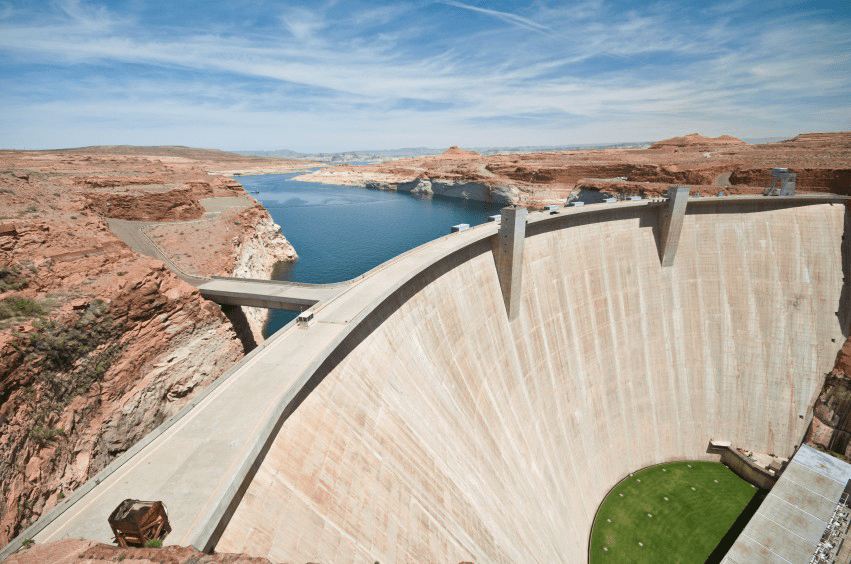

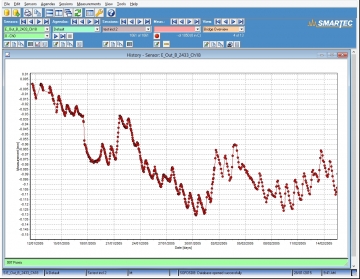

The EM Series vibrating wire strain gauge is embedded in concrete structures for monitoring variations in strain, which allows stress evaluation when the material’s modulus of elasticity is known.

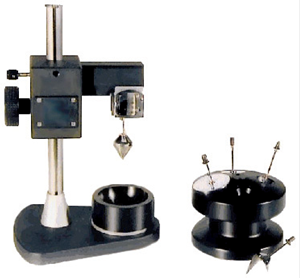

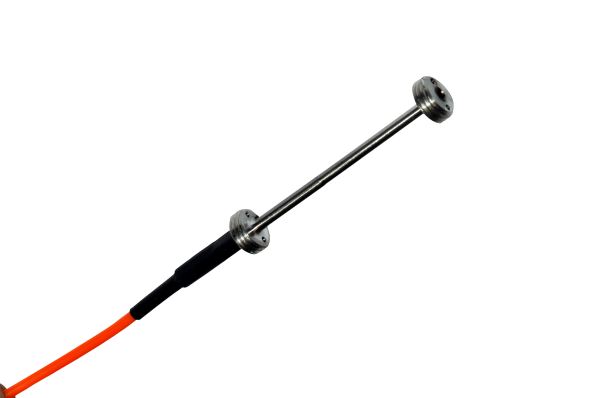

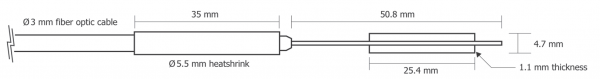

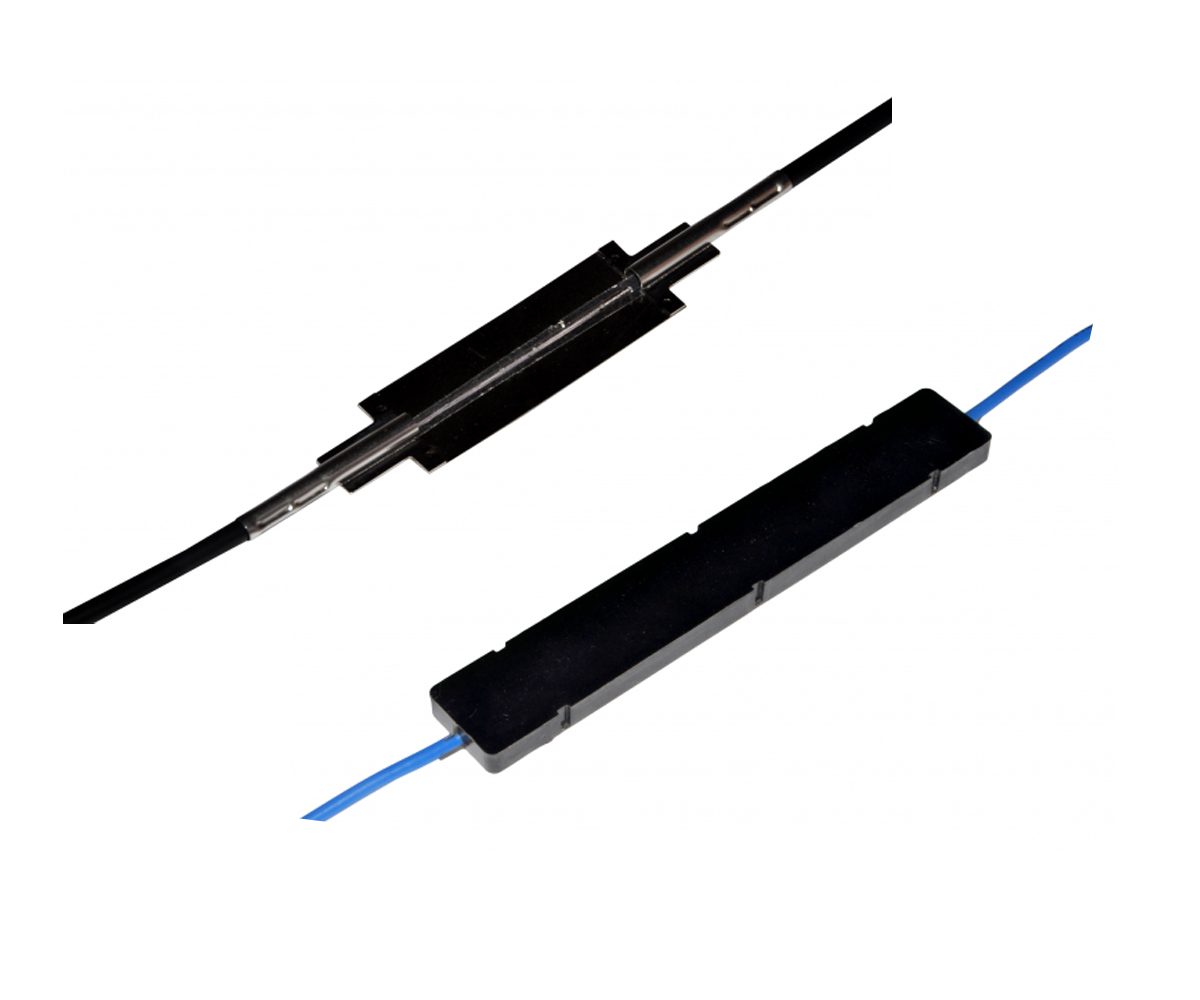

The EM is composed of two end pieces joined by a tube that protects a length of steel wire. The wire is sealed in the tube by a set of O-rings on each end piece. Both end pieces have a flat circular flange to allow transfer of concrete deformation to the wire. An electromagnet is fitted at the center of the gauge. Strain developing in the concrete modifies the tension in the wire, therefore changing its resonant frequency, which is read by the electromagnet.

The EM-5 is the standard model and is used in different types of structures. The EM-10 consists of a rugged version to be embedded in concrete with coarse aggregates. The shorter EM-2 model is designed for laboratory use or for limited spaces. Unless specified otherwise, the gauge tension is factory-adjusted at mid-range. The gauge is very compliant. It does not induce stresses in the host media and can therefore be embedded in young curing concrete as well as in hard, synthetic materials such as resins, fiberglass and urethane.A thermistor inside the EM supplies information on the effects of temperature on the materials.

Installation

There are several ways to install the gauge:

- Attaching it to a rebar with tie wire

- Inserting it directly into wet concrete or grout

- Precasting it in briquette with the same mix for subsequent embedment

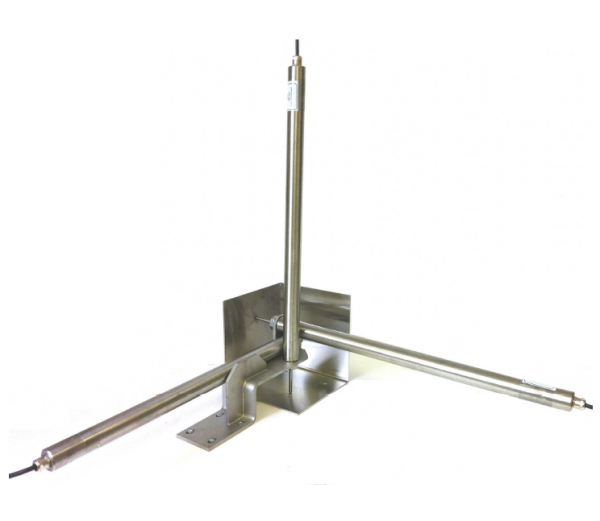

A mounting rosette that allows gauges to be precisely oriented is offered as an accessory. Also offered is a “no-stress” strain gauge that consists of a galvanized box filled with the concrete mix from the mass being poured. This unit, containing an EM, is placed adjacent to the gauge installation and is used as a reference to measure any internal variation of strain in the concrete due to aging, temperature, humidity and factors independent of external loads.

SPECIFICATIONS

| MODEL | EM-2 | EM-5 | EM-10 |

| Range | 3000 μ? | 3000 μ? | 3000 μ? |

| Accuracy | ± 0.5% F.S. | ± 0.5% F.S. | ± 0.5% F.S. |

| Resolution with MB-3TL | 0.4 μ? | 1 μ? (min.) | 0.4 μ? |

| Operating temperature | -20 to +80°C | -20 to +80°C | -20 to +80°C |

| Thermistor (see model TH-T) | 3 kΩ | 3 kΩ | 3 kΩ |

| Coil resistance | 5 Ω | 144 Ω | 144 Ω |

| Thermal coefficient | 11 ppm / °C | 11 ppm / °C | 11 ppm / °C |

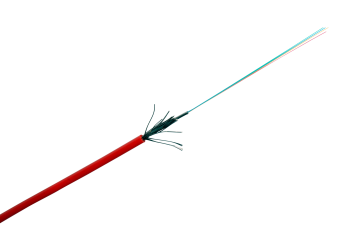

| Electrical cable |

IRC-41A IRC-41AP (optional) |

IRC-41A IRC-41AP (optional) |

IRC-41A IRC-41AP (optional) |

ORDERING INFO

Please specify:

- Model

- Cable length

Accessories:

- Rosette mounting block

- “No-stress” strain gauge

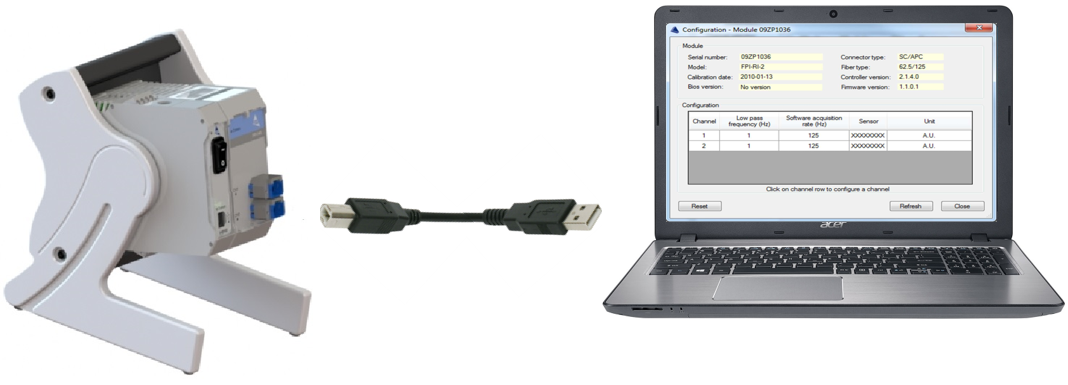

- Readout instruments: MB-3TL, SENSLOG