DMT

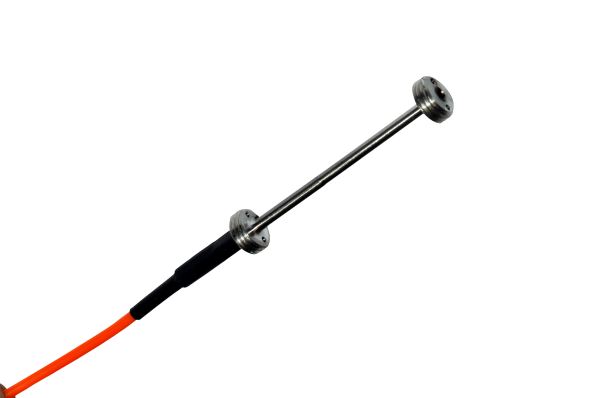

A Flat Dilatometer test consists in advancing a blade into the ground with any common field machine. At each test depth, a circular steel membrane located on one side of the blade is expanded horizontally against the soil. The pressure readings are recorded at specific moments during the membrane expansion. The blade is then advanced to the next test depth, typically with 0.20 m depth interval.

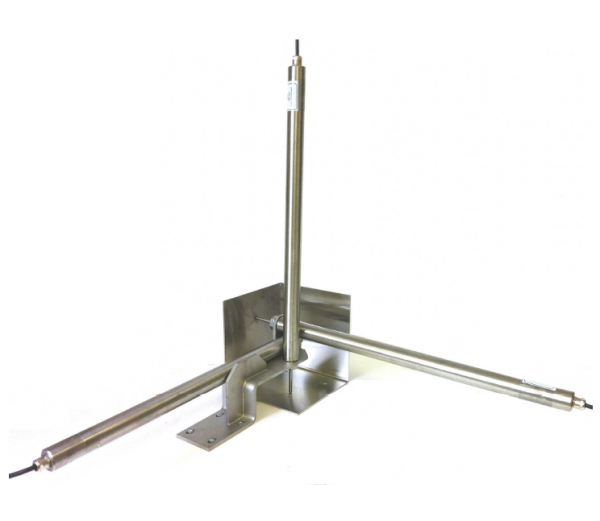

Flat dilatometer composition

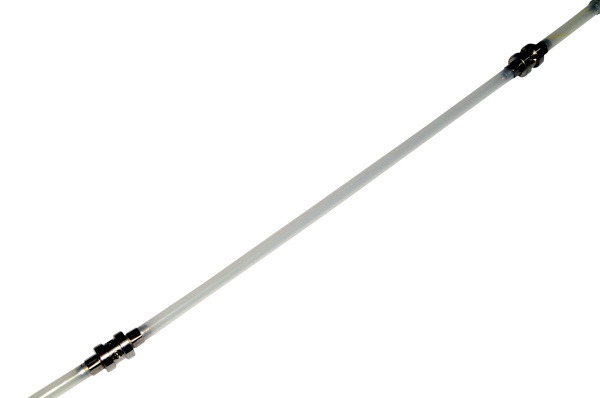

With reference to Fig. 1 (DMT Test Layout): The blade is connected to a control unit on the ground surface by a pneumatic-electrical cable running through the insertion rods and transmitting gas pressure and electrical continuity.

The blade has a cutting edge to penetrate the soil and it is advanced into the ground using common field equipment, i.e. push rigs normally used for the cone penetration test (CPT) or drill rigs. Push rods are used to transfer the thrust from the insertion rig to the blade. Advancing the blade by percussion, e.g. using the SPT hammer, is also possible. Dynamic insertion is not the preferred way, but in some countries driving is the most common insertion method.

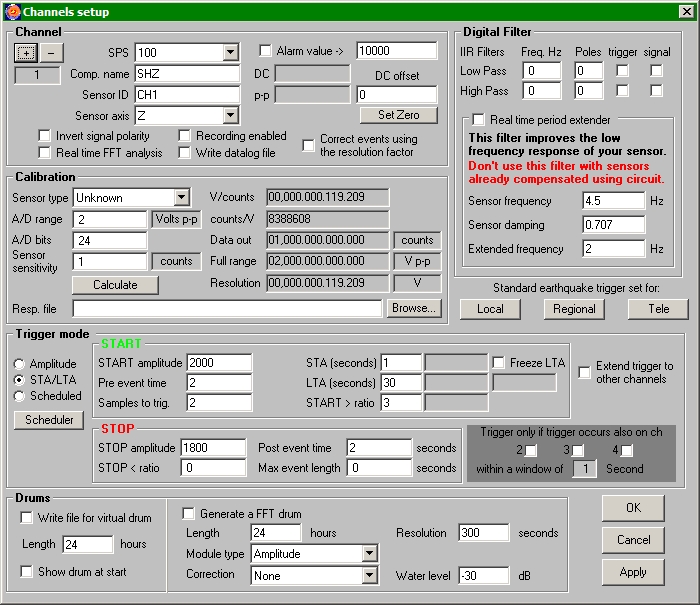

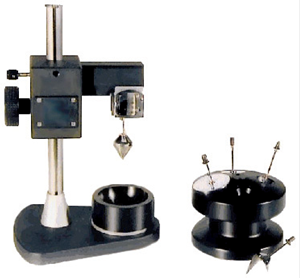

The valves on the control unit panel permit to control the gas flow to the blade and to deflate the system. The main valve provides a positive shutoff between the gas source and the control unit-blade system. The micrometer flow valve is used to control the pressurization rate during the test. The toggle vent valve allows the operator to vent quickly the system pressure to the atmosphere. The slow vent valve allows a slow deflation, in order to take the C-reading.

The general layout of the dilatometer test is shown in Fig. 1 and Fig. 4. The test starts by inserting the dilatometer into the ground. Immediately after the penetration the operator starts inflating the membrane and takes, in ≈ 15 seconds from stopping the penetration, the A-pressure. Then he continues the inflation and takes B in additional ≈ 15 seconds.

- the A-pressure is the pressure required to just begin to move the membrane against the soil (“lift-off”);

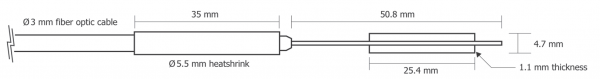

- the B-pressure is the pressure required to move the center of the membrane 1.1 mm against the soil;

- A third reading-C (“closing pressure”) can also optionally be taken by slowly deflating the membrane soon after B, using the slow vent valve, in about 30 seconds, in order to obtain the pre-insertion pore water pressure.

The blade is then advanced into the ground of one depth increment (typically 20 cm) and the procedure for taking A, B readings is repeated at each depth.

The pressure readings A, B must then be corrected by the values DA, DB determined by calibration, to take into account the membrane stiffness, and converted into p0, p1 subsequently used in the interpretations of the results.

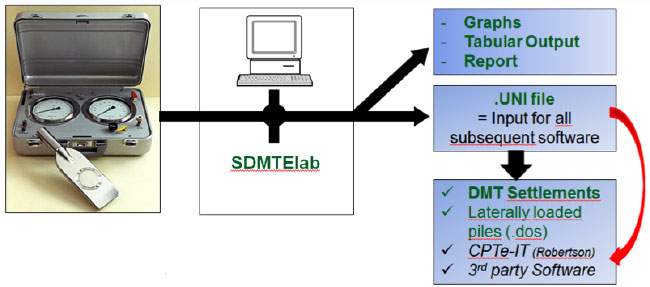

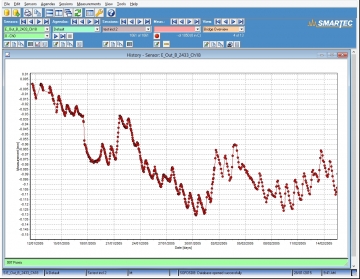

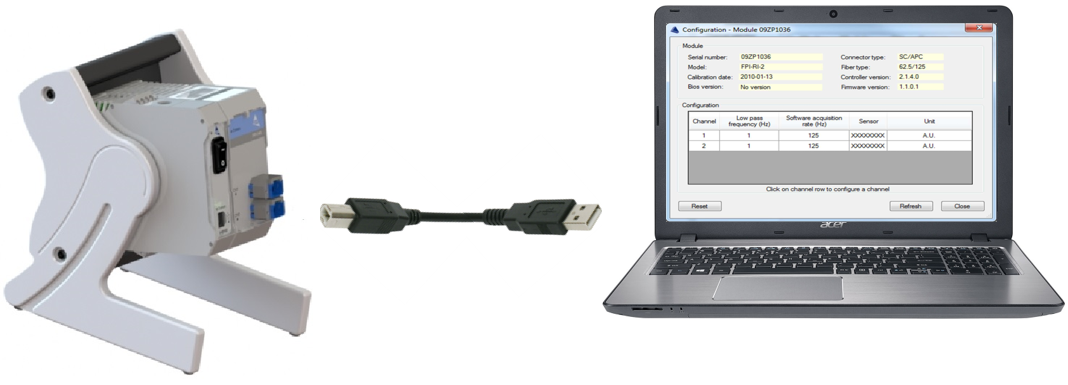

The readings acquisition can be mechanical or automatic by connecting the control unit to the computer and using the SDMTElab Software.

Dissipation Tests are also possible to get estimates of the Consolidation and Permeability Coefficient (Totani et al. 1998).

The pressure required to expand the membrane is provided by a gas tank (n.5), generally nitrogen or compressed air, connected to the control unit by a pneumatic cable. The gas tank, is equipped with a pressure regulator (suitable to gas type) which must be able to supply a regulated output pressure of at least 7-8 MPa.

The control unit is equipped with pressure gage(s), an audio-visual signal and vent valves and two pressure gages, connected in parallel, that have different scale ranges: a low-range gage (1 MPa), self-excluding when the end of the scale is reached, and a high-range gage (8 MPa). The low-range gage permits high resolution when the pression readings are small.