PISA-M – In-Place MEMS Inclinometer

SINGLE SERIAL CABLE INSTALLATION

LOW COST REAL TIME MONITORING

EXCELLENT REPEATABILITY

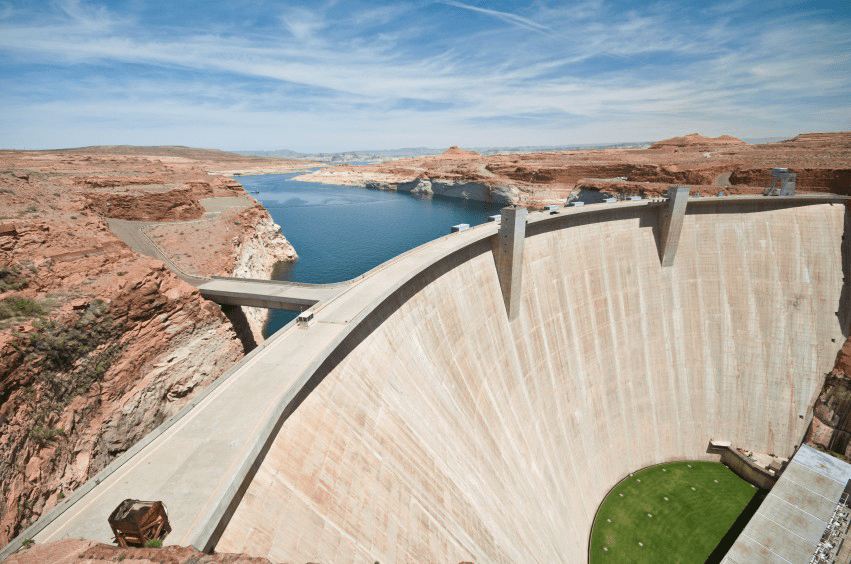

The in-place MEMS model PISA-M inclinometers are used for continuous and unattended measurements of lateral displacement of soil, rock and structures

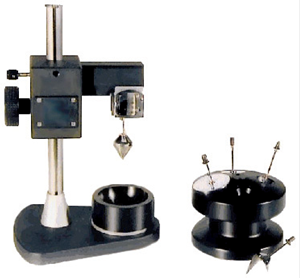

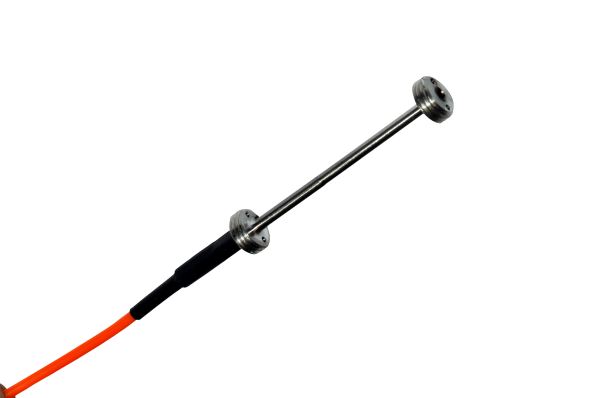

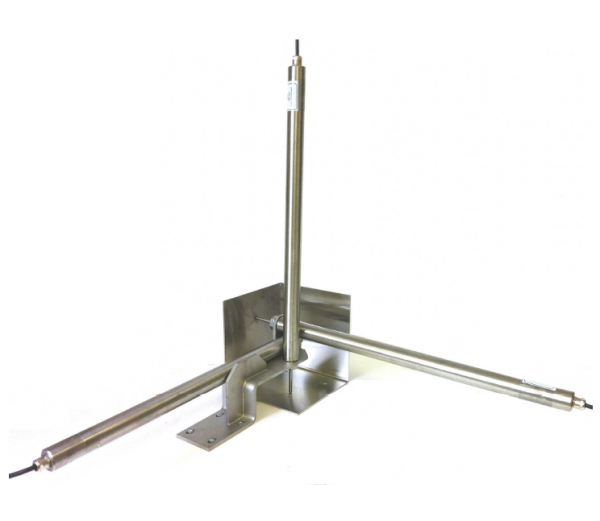

The PISA-M in-place MEMS inclinometer is either a uniaxial or biaxial tilt transducer with signal conditioning electronics, housed inside a rugged tube. A set of wheels directs the in-place MEMS inclinometer in the inclinometer casing.

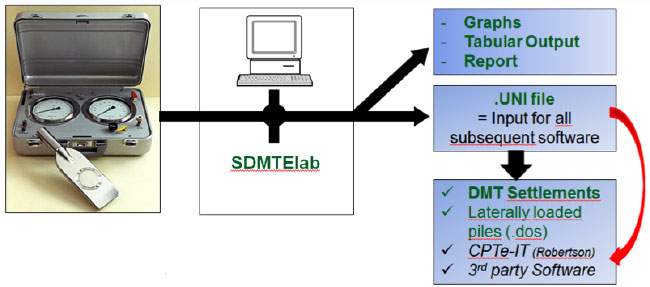

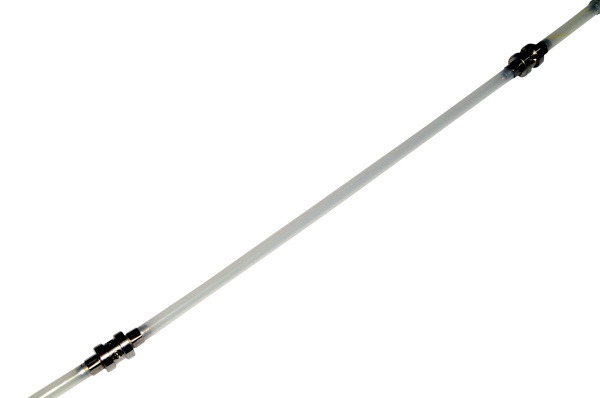

Two configurations are possible: the serial-sensor one (basic configuration) or the single-sensor configuration for monitoring a discrete zone. In the first case, only one jumper cable is required to connect the top of the sensor string to the data logger. In the second case, each sensor is connected via its own cable to the data logger.

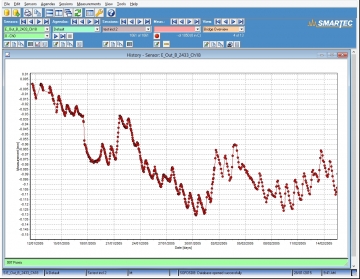

The data from the string of sensors in a borehole provides a vertical profile of the borehole. By comparing profiles over time, deflection and rate of movement can be calculated. The PISA-M can be reused on other projects once the monitoring

Specifications

| Angular range | ± 10° |

| Resolution with SENSLOG | 0.0025° |

| Repeatability | ± 0.006° |

| Output channels | One or two orthogonal tilt channels: ± 2.5 volts differential per channel |

| Power requirements | +8 to + 15 VDC |

| Housing | Stainless steel, 32 mm diameter, waterproof to 2 MPa |

| Weight | 1.6 kg with sensor and 2 m gauge length |

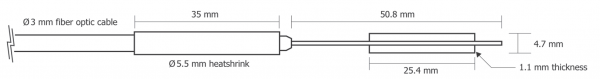

| Cable | Each sensor is supplied with cable sufficient for 3 m gauge lengths |

| Casing | 70 or 85 mm diameter casing |

| Sensor type | MEMS tilt sensors for inclination readings |

| Thermistor for temperature readings | |

| Max number of sensors * | 50 (40 m), 40 (92 m), 30 (165 m), 20 (258 m), 10 (375 m) |

* Representing nominal limits of serial sensors per length of jumper cable

Ordering Info

Please specify:

- Uniaxial or biaxial version

- Set of four guide wheels (specify casing size)

- Tubing for 1, 2 or 3 m gauge length (or custom)

- Cable length

A standard IPI system requires inclinometer casing, sensors with wheels, gauge tube, jumper cable (serial configuration), signal cable for each sensor (non-serial configuration), a suspension kit, and a data acquisition system.