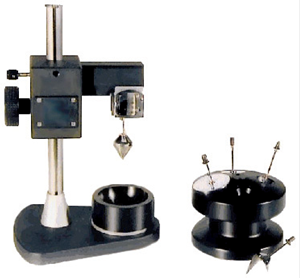

GT1-A Inclinometer Casing

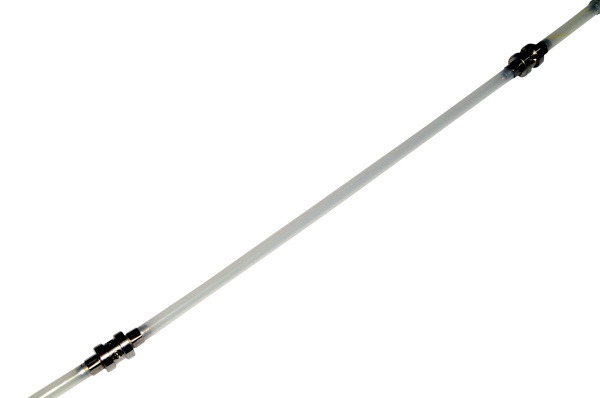

SELF-ALIGNING COUPLINGS

COMPATIBLE WITH ALL INCLINOMETER PROBES

MANUFACTURED TO TIGHT TOLERANCE

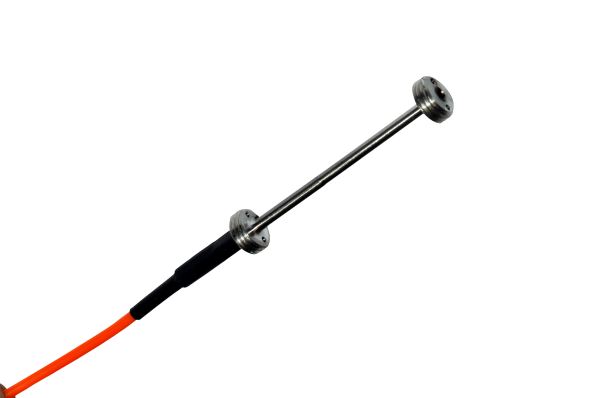

GTI-1A inclinometer casings are made of extruded ABS. The alignment key engages the internal alignment groove of the coupling. Couplings are assembled with solvent cement and rivets

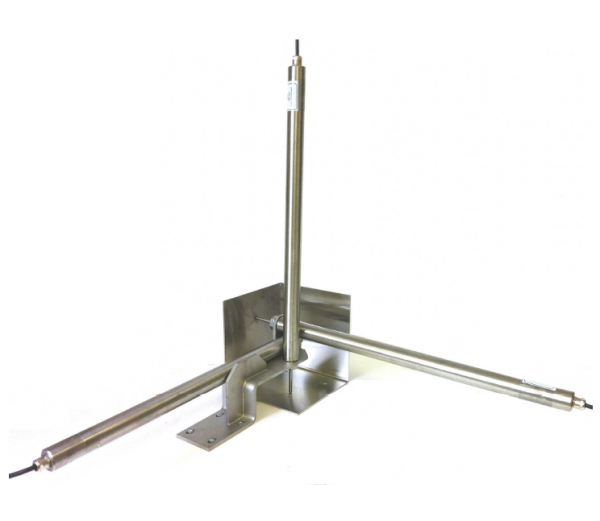

The GT1-A inclinometer casing is an extruded ABS pipe with four internal orthogonal grooves and an external alignment key. When installed in a borehole, one set of grooves is aligned in the anticipated direction of movement. The grooves act as guides for the wheels of the inclinometer probe, maintaining the orientation of the probe as it traverses the casing.

The alignment key of the GT-1A inclinometer casing engages the internal alignment groove of the coupling. Couplings are assembled with solvent cement and rivets.

Spiral surveys may be performed on deep installations, or where high accuracy is critical. Spiral data allows inclinometer data to be corrected for twisting of the casing that may occur during installation.

Guiding

Probe guidance is ensured by four 3-mm internal grooves spaced 90 degrees apart. The high accuracy guidance achieved with the GT1-A casing produces quality measurements similar to those obtained with other high quality casings. The orientation accuracy is affected more by the measuring equipment itself than by the casing.

Installation

Axial deformation: GT1-A casing length must be assembled so that no gap exists between the coupling and the casing. The standard GT1-A casing is not suitable for highly compressible soils. In these cases, GEO-LOK telescoping casing are required. The ratio of the effective section versus the total external section entails an equivalent modulus elasticity of 1000 MPa.

Sealing and grouting: Sealing method and grout composition are generally defined by the user. The GT1-A casing can withstand an external grout pressure greater than a 50-meter column of cement grout, provided that the casing is filled with water. Deeper installation will require grouting in stages.

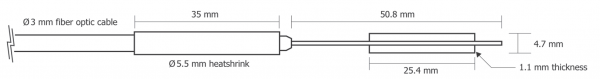

Specifications

| CASING | |

| OD | 60 mm |

| Minimal ID | 48.5 mm |

| Groove ID | 54 mm |

| Standard length | 3 m |

| Material | ABS |

| Weight | 0.8 kg/m |

| COUPLING | |

| OD | 68 mm |

| ID | 60 mm |

| Standard length | 350 mm |

| Weight | 0.270 kg |

| TOP AND BOTTOM CAPS | |

| Material | ABS and PVC |

Ordering Info

Please specify:

- Quantity of 3m sections

- Quantity of couplings

- Quantity top and bottom caps